Here is an excerpt from Axios’ article on the new wave of carbon accounting services, which are capitalising on the problem seen by companies facing pressure from new carbon regulations and customer expectations.

“Precisely tallying greenhouse gas output — and crafting strategies for reducing it — requires complex data gathering and analytics that many companies aren’t equipped to do in-house.”

“What they’re saying: “Basically every dollar businesses spend is now going to be filtered through this lens of carbon impact,” Watershed co-founder Taylor Francis said in an interview.

- “That’s because of investor demand. It’s because of regulatory expectation. It’s because of expectations from customers and employees,” he said. “It’s trillions and trillions of dollars per year that’s going to change direction based on climate as a lens.”

- Francis said clients are using Watershed to figure out steps like redesigning supply chains, choosing new vendors, and changing materials and ingredients in products.”

The U.S. Federal Trade Commission (FTC) is scheduled to begin its review of the Guides for the Use of Environmental Marketing Claims (“Green Guides”) CFR Part 260

This is a promising step forward in the process of creating a global framework that could be clearly understood and followed by companies around the world.

Citing the first chapter, Purpose, scope, and structure of the guides begins with:

“These guides set forth the Federal Trade Commission’s current views about environmental claims. The guides help marketers avoid making environmental marketing claims that are unfair or deceptive”

“The guides consist of general principles, specific guidance on the use of particular environmental claims, and examples. Claims may raise issues that are addressed by more than one example and in more than one section of the guides. The examples provide the Commission’s views on how reasonable consumers likely interpret certain claims. The guides are based on marketing to a general audience. However, when a marketer targets a particular segment of consumers, the Commission will examine how reasonable members of that group interpret the advertisement. Whether a particular claim is deceptive will depend on the net impression of the advertisement, label, or other promotional material at issue. In addition, although many examples present specific claims and options for qualifying claims, the examples do not illustrate all permissible claims or qualifications under Section 5 of the FTC Act”

source: lexology.com, All Wrapped Up: The Past, Present and Future of Recycled Content and Recyclability Claims

“The EU Green Taxonomy – and upcoming CSRD – both confirm double materiality as the basis for comprehensive non-financial information disclosure.

Value and Limitations of Materiality to Date

Ksapa have designed and updated materiality analyses for numerous Fortune 500 and financial institutions in the past decade, explored and tested multiple methodologies ranging from purely qualitative to fully quantitative approaches.

While materiality analyses are never easy and can still gain in robustness, the service aims at helping corporations and financial institutions focus on the most strategic environmental, social and ethical issues, identify the necessary management modalities, to drive transformation and meet stakeholder expectations.

THE MANY POSITIVE CONTRIBUTIONS OF MATERIALITY

Materiality has proven to be useful for companies and financial institutions for the following reasons – at the very least:

– Expands scope to better understand all the dimensions of business performance

Defined from the perspective of the impact of an organization on sustainable development and stakeholders, materiality increases companies’ focus on sustainability. This helps decision-makers better apprehend why performing on several sustainability issues is supportive of business performance

– Builds internal alignment on action plans to support business priorities and address stakeholder expectations.

An organisation’s identification of issues both financially material or material to enterprise value is incomplete unless it first reviews its material impacts on sustainable development.

Materiality clearly established why improving on select sustainability issues is good for business. It supports internal alignment, for decision-makers to take sustainability seriously as part of fulfilling the goals of their overarching plans.

– Enables better stakeholder engagement.

Applying the materiality concept provides a clear rationale on the most relevant issues. This helps companies better understand and ultimately focus on why certain issues require resources and time to engage stakeholders.

For stakeholders, materiality assessments also provide a useful perspective to zero in on the issues certain companies may be interested in, to partake in a shared agenda.

– Nurtures purpose and employee engagement

Focusing on value for the organization, society and the environment rather than financial materiality alone helps organizations engage with the United Nations’ SDG.

Materiality helps connect corporate mission statements (e.g. “we design innovative solutions to increase productivity of our clients”) with their broader responsibility of addressing urgent collective needs (e.g. “we deliver solutions for our clients to use less resources and energy – which is good for the planet and for our development”).

– Drives collective action towards the SDG

Corporate reports that address sustainable development issues material to their organizations help educate and influence the broader society on sustainable development.

A decade’s worth of materiality assessments relentlessly listed climate issues as material for all organizations. This convinced the latter to engage in coalitions and support climate regulations.

– Connects non-financial performance and financial valuation

Disclosing material sustainability issues is relevant to value creation. Several data-based studies demonstrate the direct correlation of non-financial materiality, non-financial issue management and better financial valuation

– Streamlines resources

Materiality assessments enhance decision-making, for instance with regards to resource allocation.

Companies tend to consider they lack the resources necessary to lead sustainability programs. Before exploring ways to reign in additional resources, materiality helps revisit the allocation of existing resources to target the most material issues. This can come at the expense of programs that fail to contribute positively to material issues

THE LIMITATIONS OF MATERIALITY

Combining decades’ worth of expertise and perspectives from both practitioners and academia, Ksapa is well poised to summarize the pros and cons of materiality. We use the materiality tool because we find it useful on the whole. That said, we conduct these exercises bearing in mind certain limitations :

– The absence of a standardized one-size-fits-all methodology

Materiality approaches vary considerably from one company to another. Where they prioritize mostly financially material issues, the process is rendered less robust.

– Insufficient transparency guiding conclusions

Failing to disclose the process for determining material issues reduces the perceived credibility of materiality exercises.

– The absence of third-party verification

Materiality analysis and disclosure approaches are often not included in the scope of assurance engagements. Assurance engagements of sustainability information indeed focus primarily on verifying data.

– Inaccessibility for SMEs

90% of companies are SMEs, which do not typically carry out materiality analyses – except via business associations, for instance. Simplified approaches and guidance would be helpful to empower them to conduct materiality exercises”

Source: https://ksapa.org/

“To maximise the positive outcomes of circular business models and realise their full potential for better economic growth and environmental impacts, the foundation recommends four key actions:-

-Rethink performance indicators, customer incentives, and customer experiences. Shifting to a business model based on increasing the use of products, rather than producing and selling more products, requires the business to rethink how it measures success, and to encourage its customers to opt for its circular offering through carefully designed incentives and enhanced customer experiences.

-Design products that can be used more and for longer: To maximise the economic and environmental potential of circular business models, products need to be designed and made to be physically durable and able to be remade and recycled at the end of their use.

-Co-create supply networks able to circulate products locally as well as globally. To successfully keep products in circulation, fashion supply chains – currently designed for a predictable one-way flow of products – need to be transformed into supply networks capable of circulating products locally and globally, through collaboration and the use of digital technologies.

-Scale a wider range of circular business models. Scaling a variety of circular business models that generate revenue without producing new products can increase the overall economic and environmental opportunity long term.”

https://www.innovationintextiles.com/a-700-billion-circular-opportunity/

“The Design Museum’s new exhibition on waste is not a show dedicated to recycling, according to chief curator Justin McGuirk. Waste Age, he says, is about bringing the problem of waste out from our periphery, and exploring how designers can and are using it as a material in and of itself. ‘There have been many material ages in human history – stone, bronze, steel – and we are provocatively suggesting what lies ahead could be the Waste Age’ he says.”

Continued is a digital retail platform that allows fashion brands to facilitate takebacks, renting and reselling products.

From Danish Design Centre “Designing the irresistible circular society”

Continued offers an all-in-one resale solution that enables fashion brands to

integrate circular retail models like rental or peer-to-peer resale. Their full-service

solution is a white-label digital platform that is easily integrated into a

brand’s existing sales channel and skinned according to its visual guidelines.

The platform is a turn-key ecosystem that monitors the afterlife of customer

and product behaviour and helps the brand to understand how to stay relevant

on the journey – and monetize on all activities.

Continued’s mission is to create a new consumption model in the fashion

industry that:

• reduces resource consumption

• matches consumer behaviour

• demonstrates that sustainability is good business

• extends product life and thus minimizes vulnerability to global events like

COVID-19

Recirculating clothes is the most efficient way of reducing the fashion industry’s

footprint. Continued has helped many international brands implement

circular retail in their core business.

Through high return rates, an innovative supply chain and closed-loop recycling of beverage packaging.

From Danish Design Centre “Designing the irresistible circular society”

“So far, they have managed to ensure one of the highest return rates in the world. 92% of all deposit marked beverage packaging sold on the Danish market are returned by the consumers. 90% of the collected bottles and cans are

recycled in a closed-loop to new bottles and cans. Furthermore, the packaging fees paid by the breweries and importers have been lowered by 58% over the last four years; for some specific packaging, there is no fee.

Circular economy is Dansk Retursystem’s core business. In the near future, the aim is to obtain a circular economy for 99% of all beverage packaging – environmentally (bottle-to-bottle and can-to-can) and economically (no fees).

It will require ongoing stakeholder involvement in the innovation of an even more efficient and user-friendly deposit system with the highest environmental performance.”

Does plastic have a soul?

From Danish Design Centre “Designing the irresistible circular society”

Wild Studio asks how mountains of waste and floating islands of plastic can be seen instead as a colourful, precious raw material just waiting to be collected and turned into something new.

Wild Studio is uniquely placed in terms of collaborations with a closed-loop agenda and functions as the design link between the industry, the consumer and the contributor. The loop enables municipalities, institutions and larger companies to integrate their waste strategy with Wild Studio’s design concept.

In collaborations, they are able to tell unique stories from each place. Imagine having signature outdoor furniture in a university courtyard made from plastic waste from the laboratories inside? It is a new opportunity to strengthen identity through recycling.

https://danskdesigncenter.dk/en/designing-our-circular-future

“Imagine it is the year 2050 and you live in a world that has realised a circular society. We now understand that everything – living and non-living – is connected.

We own nothing. We rent, share and barter the things we need with others in our immediate environment. It is unthinkable for you to throw anything away. There is no trash. None.

Nature is the ultimate stakeholder. We all recognise the intelligence and integrity of Nature (yes, we spell it with capital “N”). We listen to Nature. Fossil fuels are illegal.

Cars have vanished from cities. For long rides, they use electric caravans powered by renewable energy.

The marginalised voices and communities are now heard. Life is simple. Your city inspires you to live in balance with art, music, nature, dialogue, pauses, space to breathe.

If you can imagine it, you can design it

This story of a circular society may sound utopian, perhaps even naive. Maybe it sounds like a dream. But it is a fundamental truth in our world that the future must be imagined before it can be created. That is the power of design. Or, more precisely, that is the power of speculative design that thrives on imagination and aims to open up new perspectives on the wicked problems of our time.”

Christian Bason – CEO, Danish Design Centre

From linear to circular

Globally, resource extraction and processing account for 90% of biodiversity loss and water stress, and the production and consumption of materials account for almost half of global greenhouse gas emissions. In other words, conventional mitigation strategies such as switching to renewable energy and

enhancing energy efficiency will only bring us halfway to carbon neutrality in 2050.

Design is a key factor when it comes to delivering the sustainable growth of the future. Around 80% of a product’s environmental footprint is locked in at the design phase – if not more.

The passion game

The real triggers for a successful circular economy are found in the creative, innovative and passionate enablers.

We need to organise everyone to join the discussions, commit, collaborate and execute. Supporting this type of mission-driven partnership across sectors is a key motivation for BLOXHUB: to create a platform for unlocking joint innovations that can develop scalable circular solutions. Here, designers, tech startups and architects work closely, creatively and respectfully together with policy makers and investors.

Employing Design for Disassembly as a key principle

In collaboration with In Futurum and the Danish Design Centre, Tom Rossau and his company have developed three new solutions to reduce their carbon emissions through circular principles that will be implemented in the business:

• A flat-pack product that reduces packaging waste by up to 80%

• A cleaning kit to prolong the lifespan of products

• Design for Disassembly principles that make it possible to repair lamps at

home, minimising the need for return transport, extending a product’s lifespan and allowing the disassembled lamp a new afterlife

REFLOW is an EU Horizon 2020 project coordinated by Copenhagen Business

School.

REFLOW unites 28 European multi-disciplinary partners to co-create circular and regenerative cities, bridging the gap between private and public institutions, academia and the maker movement.

The project is guided by the REFLOW vision of a circular and regenerative

city, represented as an urban system with social and business practices

which place equal attention to social, environmental and economic impact.

Here:

• Technology is open source and represents a central enabler of positive

social and environmental change

• The urban system ensures and supports the resilience of social and

ecological systems

• Governance is collaborative and inclusive

• Knowledge is shared, and stakeholders are active and involved

Changing human behaviour means challenging existing behaviour

How does a reused product appeal positively to the emotions of the consumer? How is the consumer socially rewarded for lending, sharing or repairing a product? And how can we redesign everyday life, so that the circular choice is easier, more intuitive – or even irresistible?

Design offers concrete tools such as field research, personas, prototyping, scenario building and co-design, which allows us to understand and deeply engage both the explicit and unspoken needs of people. Building on these, triggers and design incentives that can spur new sustainable practices and norms can be identified.

While every individual can have their personal reasons to give their contribution to a sustainable and circular society, managing behavioural change should never be solely an individual responsibility. Changing behaviour

remains a hard challenge, but through the collective effort of ambitious companies, organisations, public bodies and civic society, individual change can be turned into collective action.

“Acetogens are thought to be one of the first life-forms on Earth. The ancient Earth’s atmosphere was very different to the atmosphere today — there was no oxygen, yet plentiful carbon dioxide.

Acetogens were able to recycle this carbon using chemical energy sources, such as hydrogen, in a process called gas fermentation. Today, acetogens are found in many anaerobic environments, such as in animals’ guts.

Not being able to use oxygen makes acetogens less efficient at building biomass; they are slow growers. But interestingly, it makes them more efficient producers.

For example, a typical food crop’s energy efficiency (where sunlight is turned into a product) may be around 1%. On the other hand, if solar energy was used to provide renewable hydrogen for use in gas fermentation (via acetogens), this process would have an overall energy efficiency closer to 10-15%.

This means acetogens are potentially up to twice as efficient as most current industrial processes — which makes them a cheaper and more environmentally friendly option. That is, if we can bring the technology to scale.

Gas fermentation is scaling up in China, the United States and Europe. Industrial emissions of carbon monoxide and hydrogen are being recycled into ethanol to commercially produce aviation fuel from 2022, plastic bottles from 2024 and even polyester clothes.”

The authors published “an economic assessment in Water Research to help chart a pathway towards widespread acetogen-carbon dioxide recycling […] and found economic barriers in producing some products, but not all. For instance, it is viable today to use carbon dioxide-acetogen fermentation to produce chemicals required to make perspex.”

Source: theconversation.com – authors: Jamin Wood, Bernardino Virdis, Shihu Hu

“The survey was conducted by the Boston Consulting Group and includes responses from more than 15,000 U.S., Europe and South America consumers.

Key report findings also include a majority of consumers who identify as environmentally aware, with more than two out of three consumers citing environmentally friendly, recyclable packaging as important. And of the 74% who said they would pay more for sustainable packaging, nearly one-fourth are willing to pay for an increased cost of 10% or more.”

via: Banktrack

“Published by Minderoo Foundation, the ‘Plastic Waste Makers Index’ has been developed with partners including Wood Mackenzie, and experts from the London School of Economics and Stockholm Environment Institute among others (2).

Scale of inaction and growing crisis

The report also lays bare the scale of inaction by plastic producers and how they are compounding the existing throwaway plastic waste crisis:

- A 30 per cent increase in global throwaway plastic production is projected over the next five years;

- This growth in production will lead to an extra three trillion items of throwaway plastic waste by 2025 alone;

- Recycled plastic or feedstocks account for no more than 2 per cent of global single-use plastic production, meaning 98 per cent of these plastics are produced from fuels;

- Plastic producers score woefully in a best practice assessment of the move to circular-based forms of production necessary in addressing the crisis;

- The global economic downturn caused by the coronavirus pandemic pushed down the price of oil, making fossil-fuel-based single-use plastics even more financially attractive.

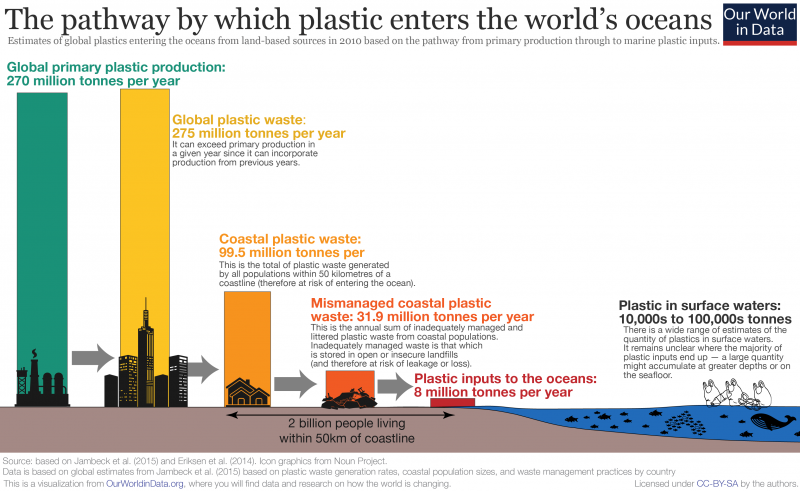

More than 130 million metric tonnes of single-use plastic ended up as waste in 2019 – almost all of which is burned, buried in landfill, or discarded directly into the environment. Nineteen pre cent of this waste – some 25 million metric tonnes – became pollution, dumped in oceans or on land (3). This is equivalent to the weight of over 23,000 blue whales, signifying the scale of the crisis, which is already having devastating ecological, social and environmental consequences.

Waste per person

The analysis shows which countries are the biggest contributors to the throwaway plastics crisis. Australia and the United States respectively produce the greatest amounts of single-use plastic waste per head of pollution, at more than 50 kilograms per person per year. In comparison, the average person in China – the largest producer of single-use plastic by volume – produces 18 kilograms of single-use plastic waste per year; in India that figure is as low as 4 kilograms per year.”

Download the report here.

The following is an extract lightly edited from this article on fast company:

“In 2020 Adidas and the sustainable, direct-to-consumer shoe brand Allbirds announced they were teaming up to make the most sustainable sneaker ever, called the Futurecraft.Footprint.”

” While an MIT study from 2013 found the average sneaker had a 13.6 kg CO2 footprint—about the same as eating about 3.5 Big Macs—the Futurecraft.Footprint comes in at 2.94 kilograms of CO2 per pair.

“The shoe’s materials are a literal fusion of Adidas and Allbirds technology. The upper—the fabric top of the shoe—is made from 70% Adidas’s recycled Primegreen polyester and 30% natural Tencel, a material made from wood pulp that Allbirds uses in its Tree line. The midsole—the bouncy foam at the bottom of the shoe—is a combination of Adidas’s Lightstrike polyurethane foam and Allbirds’ sugarcane-based SweetFoam.”

“The materials are undyed, which further saves on emissions. And yet, “it’s not just a burlap-strap brown,” as Jad Finck, head of sustainability at Allbirds, puts it. No, the shoes appear to be a true white that looks completely typical for a modern sneaker. That’s because, while materials like the upper are produced from trees, the purification process to make this textile also removes natural color”

” the stitches are influenced by the third major design goal of this shoe: for it to be as light as possible. “Weight is one of the overlooked levers of carbon footprint . . . probably the most powerful lever of reducing the carbon footprint of everything,” says Kajimura.”

According to the polish mask manufacturer Adrianno Damianii, “The Biomask type II is a biodegradable medical mask type II, which has been developed, produced, and marketed by our company […] It’s made of the same materials as regular medical masks, but it is biodegradable, which is confirmed by the laboratory results. This has been successfully achieved as we added special additives mainly to polypropylene.”

“They do not affect the properties of materials used to manufacture the mask, but make them biodegradable. It applies to spunbond nonwovens, melt blown filter fleece, elastics, and a nasal insert. This probably means that we are the first company all over the world managed to introduce on the market a biodegradable mask, which simultaneously meets the strict requirements of EN14683 for type II. An accredited Eden Research Laboratory performed biodegradation tests according to the standard ASTM D5511 / ISO 15985. The study showed biodegradation at the level of 3.5% in 32 days! Based on the findings of this test, biodegradation is expected to amount to 85% within 2.5 years! At the same time, Eden Research Laboratory conducted tests on ordinary medical masks made without additives. The results showed biodegradation of 0% within 32 days. Furthermore, an accredited Eurofins laboratory carried out the research according to EN 14683 standard, which showed that the Biomask meets the requirements for medical mask type II”.

‘people are now prepared to move into biodegradable polymers for single-use plastics, but if it turns out that it creates more problems than it’s worth, then the policy might revert back,’ said ting xu, UC berkeley professor of materials science and engineering and of chemistry. ‘we are basically saying that we are on the right track. we can solve this continuing problem of single-use plastics not being biodegradable.’

‘it turns out that composting is not enough — people want to compost in their home without getting their hands dirty, they want to compost in water,’ xu continued. ‘so, that is what we tried to see. we used warm tap water. just warm it up to the right temperature, then put it in, and we see in a few days it disappears.’

xu believes that programmed degradation could be the key to recycling many objects. ‘imagine using biodegradable glue to assemble computer circuits or even entire phones or electronics, then, when you’re done with them, dissolving the glue so that the devices fall apart and all the pieces can be reused.’

Via designboom

In this video John Oliver explains how poor is the plastic recycling rate in the United States and other curiosities related to the plastics industry.

Umbrellas are the perfect example of a product that cannot be recycled, although people WHISH it to be.

https://youtu.be/Fiu9GSOmt8E?t=541

The UK Plastics Pact. has brought together all sorts of different people & organisations with one common mission: to change the way plastic is made and used for good. It’s the first ever pact like this in the world, and is being led by sustainability experts WRAP.

The pact was made possible by the Ellen MacArthur Foundation and their new Plastics Economy work, which has set out clear steps to get to a world where plastics are valued and never become waste. The ultimate dream.

By bringing together everyone who uses plastics across the whole chain with the government, and giving everyone bold and ambitious targets to hit, we’re working together towards keeping plastic in the recycling loop rather than letting it turn into litter which pollutes the environment. The pact covers the research and innovation of new packaging which will encourage businesses to rethink and redesign the stuff they put out into the world and proactively encourage people to re-use and recycle our packaging after they’ve finished with it.

4 key targets to hit by 2025:

1. put a stop to problematic or unnecessary single-use packaging through redesign and innovation

2. 100% of plastic packaging will be reusable, recyclable or compostable

3. 70% of plastic packaging will be recycled or composted

4. 30% will be the average recycled content for all plastic packaging

source: https://www.innocentdrinks.co.uk

As stated in the biosphere press release:

“Current culture is lead to believe that plastic is not biodegradable. This is incorrect. All plastic is organic in nature and has been proven to biodegrade by microorganisms by several differant groups, some of them being high school students in Canada and Ben Gurion University scientists in Israel. This information has paved the way for BioSphere to bring to market the following technology and become a rapidly growing worldwide used technology.

The BioSphere technology allows microorganisms to produce CO2 and CH4,

both of these are the result of the consumption of the plastic. When microorganisms consume anything aerobically or anaerobically these two gases are produced. Anaerobic biodegradation produces CH4 and Aerobic biodegradation produces CO2. The BioSphere technology allows the microbes to consume the plastic product in all active microbial environments.

The Science:

BioSphere Plastic LLC technology is built on the fundamental properties of building polymers and depolymerization.

In the molecular world, the small subunits that ultimately link together to form larger molecules are called monomers, which literally means “single unit” (mono = one). When a bunch of monomers join together into a much larger molecule, they form a polymer, meaning “many units” (poly = many).

How does this “linking together” happen? There is a process by which this joining usually occurs, called dehydration synthesis. Two monomers line up next to each other, a hydrogen (H) from one monomer binds with a hydroxyl group (OH) from another monomer, and voilà! A water molecule is born: H+ + OH- = H2O.

During dehydration synthesis, two subunits, or monomers, bind to each other where they were once bound to their respective hydrogen (–H) or hydroxyl (–OH) groups.

This blissful union is presided over by an enzyme that is mainly there to help speed things along. The name of the process is dehydration synthesis because monomers are literally coming together and synthesizing a polymer by dehydrating, or removing a water molecule.

This is how a polymer is formed. How a polymer is hydrolyzed is the basis of our technology.

This is done by the addition of water between the bonds. Now the question that people wonder is how we do just that.

Anytime you allow water to attack the bonds between polymers this allows for hydrolyzing of the bonds which in turn lowers the molecular weight of the product. The addition of BioSphere additive introductes key elements into the polymer structure which allow hydrolyzation of the polymer.

Microbes produce enzymes, these enzymes are part of the organic cycle which produce reactions. Reactions by enzymes which are produced only by microorganisms create catalysts which are formed by gram-negative and grampositive bacteria. The catalysts accelerate metabolic reactions. The metabolic reaction we use (even though there are multiple metabolic pathways in this reaction) is the carbohydrate metabolism.

We boost the ATP to carry more energy back to the pyruvic acid (Anaerobic) or the Acetyl CoA(Aerobic) cycles. This in turn creates proteins or lipids from the Pyruvic Acid cycle (Anaerobic) and acetyl CoA cycle(Aerobic).

This process created by microorganisms does not occur on the shelf, nor does it occur when water is in contact with the plastic. This reaction of microorganisms only occurs when the product is placed in an active microbial environment. BioSphere additive attracts over 600 differant types of microbes to consume the polymer. The enzymes that the microbes produce react with the BioSphere addtiive creating a catalyst that breaks down the molecular weight of the polymer making it easier for microorganisms to consume the plastic. This is called biodegradation.”

https://www.biosphereplastic.com/

“In 2015, polling group Nielsen surveyed 30,000 people in 60 countries around the world. They wanted to know what influences the way consumers feel about brands – and how those feelings impact buying behaviour.

The survey found that two-thirds of respondents would happily pay more for sustainable goods.”

Source: world economic forum website https://www.weforum.org/agenda/2018/09/sustainability-is-now-mission-critical-for-businesses-heres-why/

“Recent success in reducing carrier bag (PE) and drinks bottles (PET) waste in Europe suggests lifestyle adjustments are possible, but plastic is ingrained in modern society and a future free from plastic seems unlikely. Complete alteration of human behaviour is difficult to attain, as indicated by the fact that only 9% of plastic waste is recycled3. Therefore in addition to these three solutions to the plastic waste problem (reducing, reusing and recycling), we need a fundamental change in order to make a noticeable impact on the plastic waste seeping into our environment. A new plastic future in which biodegradable polymers replace conventional plastics could be the answer.”

source: https://www.nature.com/articles/s41467-018-04565-2

“Some bacteria think plastic is fantastic

Bacteria isolated from outside a bottle-recycling facility can break down and metabolize plastic. The proliferation of plastics in consumer products, from bottles to clothing, has resulted in the release of countless tons of plastics into the environment.

Yoshida et al. show how the biodegradation of plastics by specialized bacteria could be a viable bioremediation strategy (see the Perspective by Bornscheuer).

The new species. Ideonella sakaiensis, breaks down the plastic by using two

enzymes to hydrolyze PET and a primary reaction intermediate, eventually yielding basic building blocks for growth.”

Source: Science. p. 1196: See also p. 1154 – Bacteria found near a plastics recycling plant can degrade plastic

Source: https://ourworldindata.org/plastic-pollution

Thanks www.trillionsgmbh.com for the sources

“ReverteTM is an oxo-biodegradable additive which is added directly into the film manufacturing process to standard PE, PP & PET to impart this property, with almost no physical impact on the processing of the polymer.”

Oxo-Biodegradable polymers

“These polymers undergo controlled degradation through the incorporation of a ‘prodegradant’ additive (an additive that can trigger and accelerate the degradation process). These polymers undergo accelerated oxidative defined degradation initiated by natural daylight, heat and/or mechanical stress, and embrittle in the environment and erode under the influence of weathering.Reverte™ produces a plastic product with equivalent performance characteristics than the present non-degradables, is cost competitive and results in a product will totally and harmlessly disintegrate in multiple environments, commencing at a predetermined time.”

Source: https://www.bioplastics.com.sg/faqs

Fairphone is designed for a circular life-cycle, because every component can be replaced, plus it utilizes recycled plastic.

Food companies trying to reduce their consumption of plastic have a big problem — it’s hard to find suitable recycled material. Nestlé says it’s willing to spend more than $2 billion to try and fix that.

The world’s biggest foodcompany said in a statement Thursday that it would cut costs in other parts of its business to free up more than 1.5 billion Swiss francs ($1.6 billion) to buy 2 million metric tons of recycled plastic between now and 2025.

Nestlé said it would be paying above the market rate for the recycled material, part of its strategy to alleviate a shortage of used plastics suitable for food packaging by luring new suppliers into the business. Doing so shouldhelp the company meet its goal of reducing its use of virgin plastics by a third by 2025.

“Making recycled plastics safe for food is an enormous challenge for our industry,” Mark Schneider, chief executive of Nestlé, said in a statement.

“That is why in addition to minimizing plastics use and collecting waste, we want to close the loop and make more plastics infinitely recyclable,” he added

Source: https://ktvz.com/money/2020/01/17/nestle-is-spending-billions-to-create-a-market-for-recycled-plastics/

“The vision of INDIANES is that banana fiber is the solution to the environmental crisis caused by the textile and fashion industry. Banana fiber was used for centuries by Colombian communities and does not require any water or extension of land for cultivation, since it is obtained from the residues of banana agriculture.”

“Mattel announced its goal to achieve 100% recycled, recyclable or bio-based plastics materials in both its products and packaging by 2030.

This new goal expands the Company’s Environmental Sustainable Sourcing Principles that were announced in 2011. The Company now sources 93% of the paper and wood fiber used in its packaging and products from recycled or Forest Stewardship Council (FSC) content, surpassing its 2018 goal of 90%. In addition, the Company has adopted the How2Recycle label, a standardized labeling system that clearly communicates recycling instructions to the public.”

“As soon as we’d received the Generation 1 shoes, we were able to start Phase 2. We collected the shoes, recycled them, kept them in our supply chain and ultimately remade the recycled material into new running shoe components. The material is melted and developed into new pellets, which are heated to form new components including the eyelets and outsole. Virgin TPU material is used to create the remaining components of the midsole and upper. The remade and new materials are fused together to create Generation 2: a running shoe in a blue colourway, that remains one material and is still 100% recyclable for the next generation. So, this is where we are today: launching the next generation of FUTURECRAFT.LOOP and one step closer to a consumer reality – all in the space of just eight months. A first for adidas”.

adidas strengthens its commitment to tackling plastic waste with the reveal of FUTURECRAFT.LOOP – a 100% recyclable performance running shoe. Together with Parley for the Oceans, adidas introduced in

The Ellen MacArthur Foundation has appointed the London office of Hill+Knowlton Strategies (H+K) to drive greater awareness of the circular economy.

[separator_line]

Based in the Netherlands, Boldking has created a product / service for environmentally conscious customers with an attractive design at half the price.

Source: https://www.boldking.com/

This Co.Project brought together a range of CE100 members to explore case studies and examples of how retailers can engage with their customers post point of sale to unlock economic opportunities.

Cranfield University, Arizona State University and PA Consulting Group surveyed 250 consumers in the US, UK, France and Spain on post-sale behaviours – with a survey response rate of 72 per cent. The conclusions in this report reflect the analysis of the survey results, company case stories and the authors’ experience across a range of markets and geographies.

CE100 Co.Project partners that contributed to the wider report include Stuffstr, eBay, Kingfisher, Philips, Waste and Resources Action Programme (WRAP) and the Ellen MacArthur Foundation.

This report was co-authored by PA, Walmart and the Ellen MacArthur Foundation.

“In a new plastics economy, plastics will never become waste or enter the ocean in the first place,” said Ellen MacArthur, an ex-sailor who began her eponymous foundation in 2009.

“These winning innovations show what’s possible when the principles of a circular economy are embraced. Clean-ups continue to play an important role in dealing with the consequences of the waste plastic crisis, but we know we must do more. We urgently need solutions that address the root causes of the problem, not just the symptoms.

“To get there will require new levels of commitment and collaboration from industry, governments, designers and startups,” she continued. “I hope these innovations will inspire even more progress, helping to build a system in which all plastic materials are reused, recycled or safely composted.”

thanks to dezeen.com

Here’s some useful links:

https://www.newplasticseconomy.org/

https://www.circulardesignguide.com/

https://www.newplasticseconomy.org/projects/innovation-prize

This article by Anne Marie Mohan, senior editor at packworld.com shows every advancement made on biopolymers applied on the packaging industry.

The industrial sector is at its beginnings but huge players such as PepsiCo are partnering with companies active on developing new bopolymers, which are seen as a natural evolution of the actual plastic industry.

New kinds of manufacturing byproducts are being used to produce biopolymers.

Mixed with traditional plastics, these materials not only reduce drastically the carbon footprint of the products on which are applied, but can offer superior properties.

A new generation of sustainably minded designers is pioneering ways of using recycled plastic as a raw material, as concern over pollution increases.

For decades, “virgin plastic” has been used to produce everything from food packaging to furniture. But, as the environmental impact of this material becomes more apparent, an increasing number of designers are exploring alternatives. https://www.dezeen.com/2018/02/02/recycled-plastic-only-choice-say-designers/

“We’re living in a culture where everything we consume and interact with can be tailored to our personal needs, and this expectation for the customisation of our lives and surroundings has – in recent years – found its way to our possessions. But what does the rise of personalisation mean for design? How does it change our products and the design process behind them? Last night It’s Nice That and IKEA hosted The Future of Design: How Personalisation is on the rise for the mass audience, a panel discussion exploring the topic, featuring four experts in the field”.

Via ItsNiceThat: https://goo.gl/dJeRLe

Behind the scenes of the process of making of the YPPERLIG monobloc chair

Here you will find an excerpt from the latest paper from the European commission “A European Strategy for Plastics in a Circular Economy”:

Plastic is an important and ubiquitous material in our economy and daily lives. It has multiple functions that help tackle a number of the challenges facing our society. Light and innovative materials in cars or planes save fuel and cut CO2 emissions. High-performance insulation materials help us save on energy bills. In packaging, plastics help ensure food safety and reduce food waste. Combined with 3D printing, bio-compatible plastic materials can save human lives by enabling medical innovation.

However, too often the way plastics are currently produced, used and discarded fails to capture the economic benefits of a more ‘circular’ approach and harms the environment. There is an urgent need to tackle the environmental problems that today cast a long shadow over the production, use and consumption of plastics. The million tonnes of plastic litter that end up in the oceans every year are one of their most visible and alarming signs of these problems, causing growing public concern.

Rethinking and improving the functioning of such a complex value chain requires efforts and greater cooperation by all its key players, from plastics producers to recyclers, retailers and consumers. It also calls for innovation and a shared vision to drive investment in the right direction. The plastics industry is very important to the European economy, and increasing its sustainability can bring new opportunities for innovation, competitiveness and job creation, in line with the objectives pursued by the renewed EU Industrial Policy Strategy. 1

In December 2015, the Commission adopted an EU Action Plan for a circular economy. 2 There, it identified plastics as a key priority and committed itself to ‘prepare a strategy addressing the challenges posed by plastics throughout the value chain and taking into account their entire life-cycle’. In 2017, the Commission confirmed it would focus on plastics production and use and work towards the goal of ensuring that all plastic packaging is recyclable by 2030.”

[…]

‘A vision for Europe’s new plastics economy’

A smart, innovative and sustainable plastics industry, where design and production fully respects the needs of reuse, repair, and recycling, brings growth and jobs to Europe and helps cut EU’s greenhouse gas emissions and dependence on imported fossil fuels.

−Plastics and products containing plastics are designed to allow for greater durability, reuse and high-quality recycling. By 2030, all plastics packaging placed on the EU market is either reusable or can be recycled in a cost-effective manner.

−Changes in production and design enable higher plastics recycling rates for all key applications. By 2030, more than half of plastics waste generated in Europe is recycled. Separate collection of plastics waste reaches very high levels. Recycling of plastics packaging waste achieves levels comparable with those of other packaging materials.

−EU plastics recycling capacity is significantly extended and modernised. By 2030, sorting and recycling capacity has increased fourfold since 2015, leading to the creation of 200 000 new jobs, spread all across Europe. 19

−Thanks to improved separate collection and investment in innovation, skills and capacity upscaling, export of poorly sorted plastics waste has been phased out. Recycled plastics have become an increasingly valuable feedstock for industries, both at home and abroad.

−The plastics value chain is far more integrated, and the chemical industry works closely with plastics recyclers to help them find wider and higher value applications for their output. Substances hampering recycling processes have been replaced or phased out.

−The market for recycled and innovative plastics is successfully established, with clear growth perspectives as more products incorporate some recycled content. Demand for recycled plastics in Europe has grown four-fold, providing a stable flow of revenues for the recycling sector and job security for its growing workforce.

−More plastic recycling helps reduce Europe’s dependence on imported fossil fuel and cut CO2 emissions, in line with commitments under the Paris Agreement.

−Innovative materials and alternative feedstocks for plastic production are developed and used where evidence clearly shows that they are more sustainable compared to the non-renewable alternatives. This supports efforts on decarbonisation and creating additional opportunities for growth.

−Europe confirms its leadership in sorting and recycling equipment and technologies. Exports rise in lockstep with global demand for more sustainable ways of processing end-of-life plastics.

In Europe, citizens, government and industry support more sustainable and safer consumption and production patterns for plastics. This provides a fertile ground for social innovation and entrepreneurship, creating a wealth of opportunities for all Europeans.

−Plastic waste generation is decoupled from growth. Citizens are aware of the need to avoid waste, and make choices accordingly. Consumers, as key players, are incentivised, made aware of key benefits and thus enabled to contribute actively to the transition. Better design, new business models and innovative products emerge that offer more sustainable consumption patterns.

−Many entrepreneurs see the need for more resolute action on plastics waste prevention as a business opportunity. Increasingly, new companies emerge that provide circular solutions, such as reverse logistics for packaging or alternatives to disposable plastics, and they benefit from the development of digitisation.

−The leakage of plastics into the environment decreases drastically. Effective waste collection systems, combined with a drop in waste generation and with increased consumer awareness, avoid litter and ensure that waste is handled appropriately. Marine litter from sea-based sources such as ships, fishing and aquaculture are significantly reduced. Cleaner beaches and seas foster activities such as tourism and fisheries, and preserve fragile ecosystems. All major European cities are much cleaner.

−Innovative solutions are developed to prevent microplastics from reaching the seas. Their origin, routes of travel, and effects on human health are better understood, and industry and public authorities are working together to prevent them from ending up in our oceans and our air, drinking water or on our plates.

−The EU is taking a leading role in a global dynamic, with countries engaging and cooperating to halt the flow of plastics into the oceans and taking remedial action against plastics waste already accumulated. Best practices are disseminated widely, scientific knowledge improves, citizens mobilise, and innovators and scientists develop solutions that can be applied worldwide.

[…]

Improving the economics and quality of plastics recycling

Stepping up the recycling of plastics can bring significant environmental and economic benefits. Higher levels of plastic recycling, comparable with those of other materials, will only be achieved by improving the way plastics and plastics articles are produced and designed. It will also require increased cooperation across the value chain: from industry, plastics manufacturers and converters to public and private waste management companies. Specifically, key players should work together to:

−improve design and support innovation to make plastics and plastic products easier to recycle;

−expand and improve the separate collection of plastic waste, to ensure quality inputs to the recycling industry;

−expand and modernise the EU’s sorting and recycling capacity;

−create viable markets for recycled and renewable plastics.

Using a plant-derived solvent called GVL (gamma-Valerolactone), University of Wisconsin-Madison Professor of Chemical and Biological Engineering James Dumesic and his team have developed an economical and high-yielding way of producing furandicarboxylic acid, or FDCA. One of 12 chemicals the U.S. Department of Energy calls critical to forging a “green” chemical industry, FDCA is a necessary precursor to a renewable plastic called PEF (or polyethylene furanoate) as well as to a number of polyesters and polyurethanes.

“Until now, FDCA has had a very low solubility in practically any solvent you make it in,” says Ali Hussain Motagamwala, a UW-Madison graduate student in chemical and biological engineering and co-author of the study. “You have to use a lot of solvent to get a small amount of FDCA, and you end up with high separation costs and undesirable waste products.”

Motagamwala and colleagues’ new process begins with fructose, which they convert in a two-step process to FDCA in a solvent system composed of one part GVL and one part water. The end result is a high yield of FDCA that easily separates from the solvent as a white powder upon cooling.

The team’s techno-economic analysis suggests that the process could currently produce FDCA at a minimum selling price of $1,490 per ton. With improvements, including lowering the cost of feedstock and reducing the reaction time, the price could reach $1,310 per ton, which would make their FDCA cost-competitive with some fossil fuel-derived plastic precursors.

“We think this is the streamlined and inexpensive approach to making FDCA that many people in the plastics industry have been waiting for,” says Dumesic. “Our hope is that this research opens the door even further to cost-competitive renewable plastics.”

Credit: UW–Madison image by Ali Hussain Motagamwala and James Runde